The "How" of Hands

A detailed look at how TUDOR Snowflake hands are produced.

What signature design element sets a TUDOR watch apart? The Snowflake hands, of course. They first appeared in TUDOR’s 1969 catalogue on the dive watch references 7016 and 7021. The idea behind the hands was simple: create maximum legibility by allowing for generous application of luminescent material, therefore making the watch more functional and relevant to divers who relied on their watch in the water. The design was used until the mid-eighties for diving watches exclusively, the “snowflake” configuration then re-entered the Tudor collection at Baselworld 2012 with the combined launch of the popular Black Bay and Pelagos models. Today it remains the single most proprietary and recognized TUDOR design element.

The role of the dive watch may have changed, but the Snowflake hand has remained. It’s the quickest way to recognize a TUDOR watch. But just how is the unique design achieved?

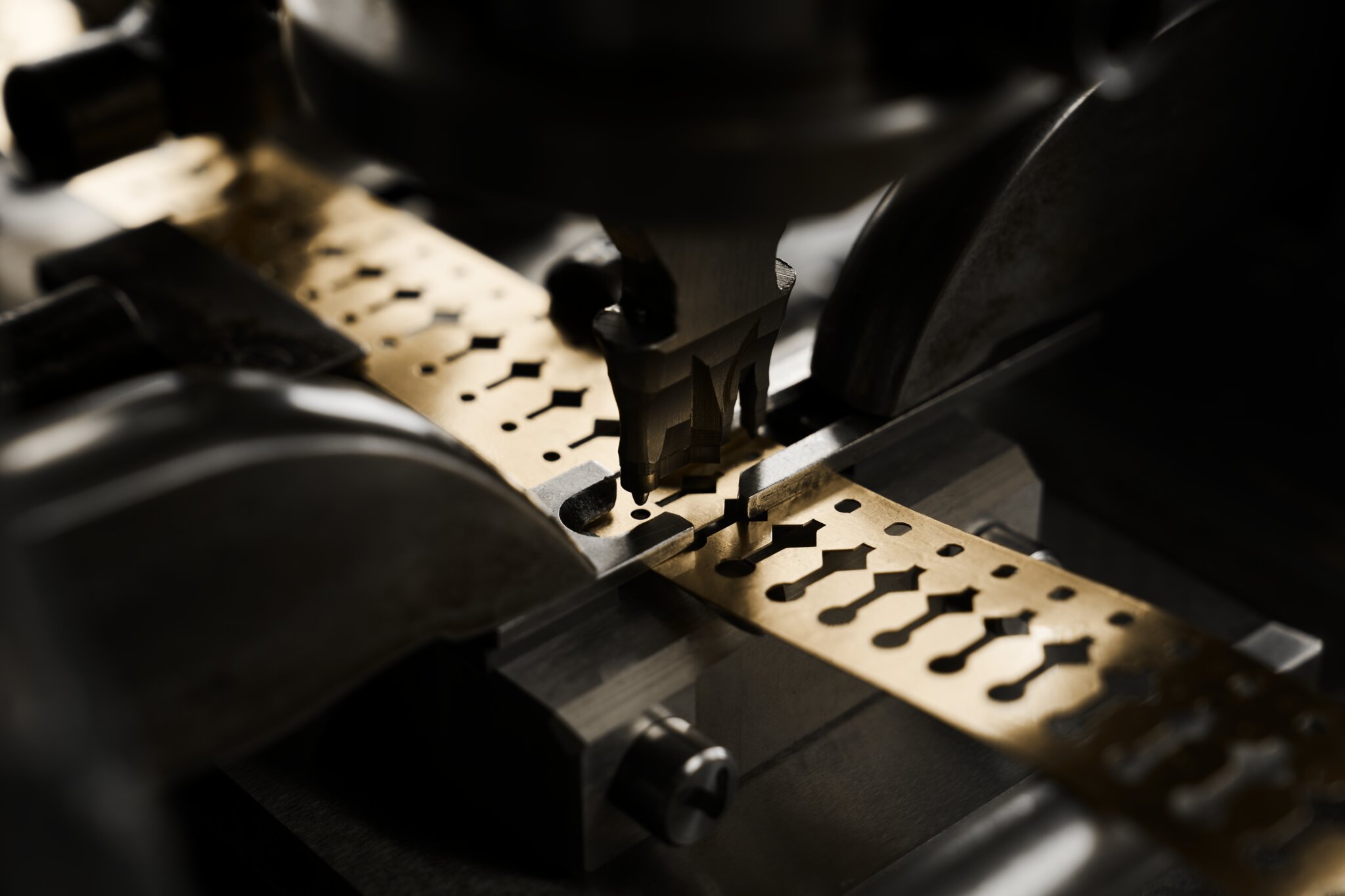

It all starts with a thin, but strong, brass ribbon. The metal ribbon is roughly the thickness of the watch hands, and that is to say it’s very thin. This brass ribbon is first unfurled, and then the shape of a snowflake hand is punched out of it by a stamping machine. The pattern that’s created eventually becomes the “inside” of the Snowflake hands. In order to create the entire hand, the diameter of the pattern is enlarged and the machine stamps the pattern again, but this time the whole hand is produced, only it’s hollow—there is no material filling the hand at this stage.

The hand is polished and finished before being filled with luminescent material for a long-lasting glow. After using a proprietary technique to fill the hands, they are placed on a card and prepared for a watchmaker to install them by hand. This part of the process is impossible to do by machine, making the watchmaker a crucial part of this phase of assembly. After all, the hands are a part of the watch that you see every time you look for the time.

Watches mentioned

Related articles

View all news

Take a Behind-The-Scenes Look at How TUDOR Pelagos Dials are Made

While it may look simple, so much goes into making the dial of the TUDOR Pelagos Ultra.

#craft

SRAM and Tudor Pro Cycling Craft a Masterpiece in Le Locle

Yes, there’s a watch—but that’s not the only masterpiece involved at the Tudor Manufacture.

#craft

Dissecting the Details of the TUDOR Bronze Bracelet

For the first time ever TUDOR has produced a bracelet entirely made from bronze.

#craft

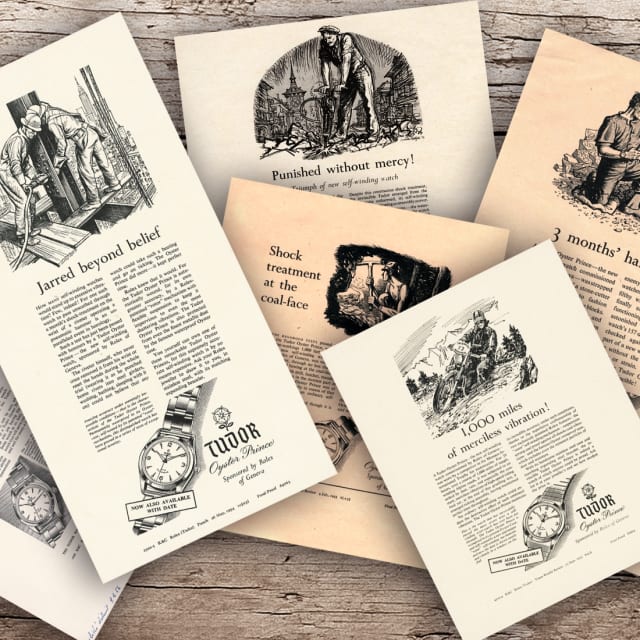

These 1950s Ads Shed Light On TUDOR’s Guiding Principles

The “Trial of Destruction” as campaign tells you everything you need to know about what drives TUDOR to make the toughest watches possible.

#craft